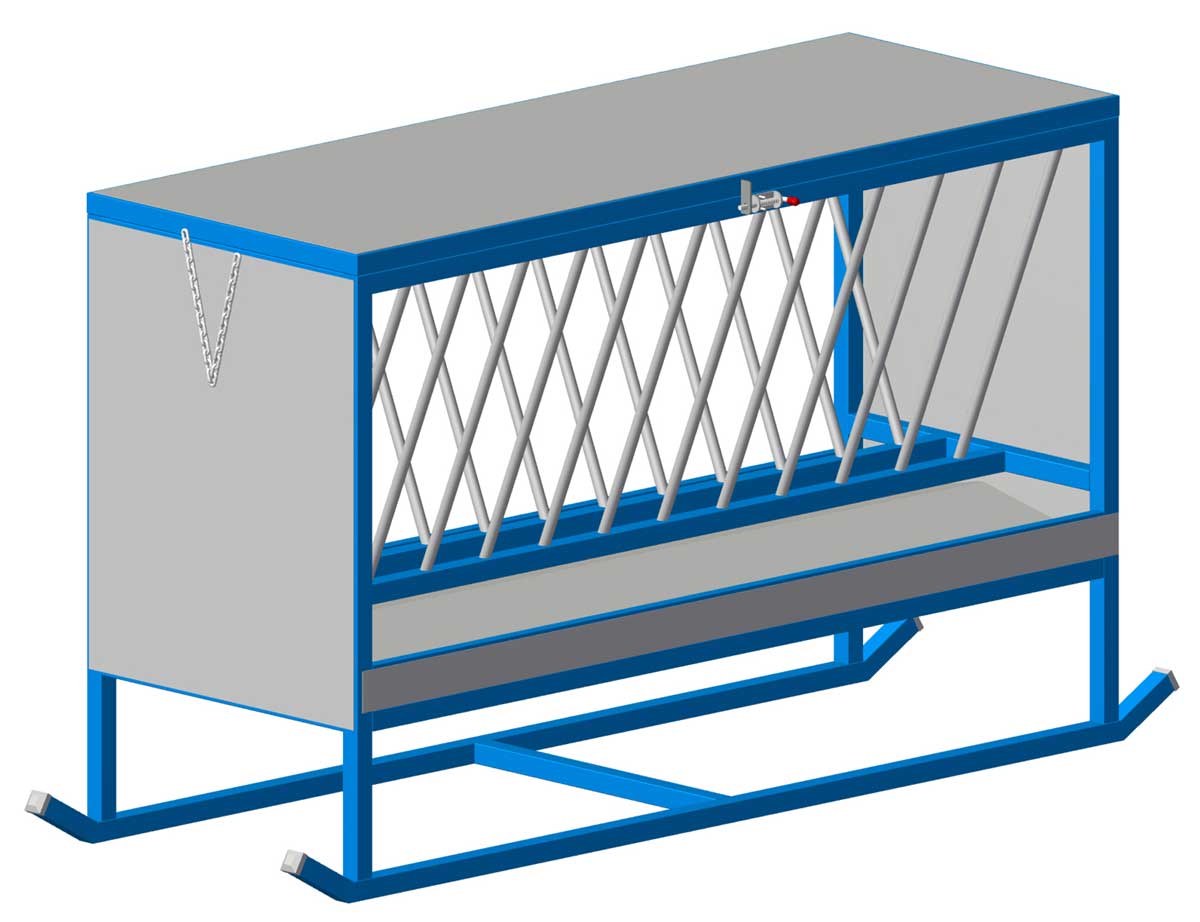

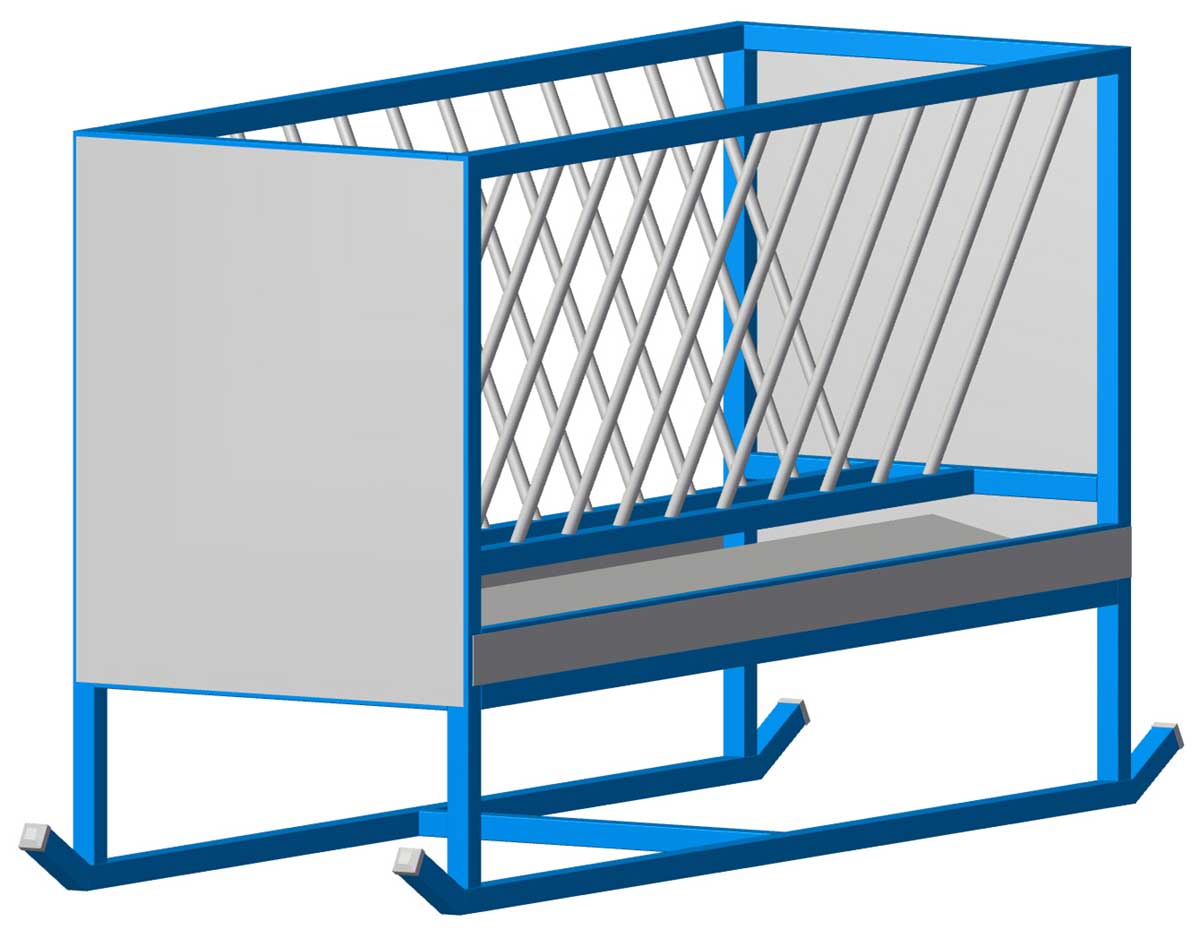

This cattle hay feeder is an important part of the farm equipment inventory. It allows the hay to be available to your cattle as they require it, keeps it off the ground so that the cattle don’t spoil it and with the addition of the roof, the chances of the hay getting wet are minimised.

Free Steel Cattle 8 Foot Hay Feeder Plans

| Materials Required | |||

|---|---|---|---|

| Item Number | Material | Length | Quantity |

| 1 | 50x50x2.0 SHS | 1450mm | 4 |

| 2 | 50x50x2.0 SHS | 2500mm | 2 |

| 3 | 50x50x2.0 SHS | 200mm | 4 |

| 4 | 50x50x2.0 SHS | 2460mm | 2 |

| 4A | 50x50x2.0 SHS | 2360mm | 2 |

| 5 | 50x50x2.0 SHS | 820mm | 2 |

| 6 | 50x50x2.0 SHS | 820mm | 1 |

| 7 | 50x50x2.0 SHS | 820mm | 2 |

| 8 | 50x50x2.0 SHS | 820mm | 2 |

| 9 | 50x50x2.0 SHS | 2360mm | 4 |

| 9A | 30x30x2.0 SHS | 2360mm | 4 |

| 10 | 50x50x2.0 SHS | 2460mm | 2 |

| 11 | 50x50x2.0 SHS | 920mm | 2 |

| 12 | 50x50x2.0 SHS | 820mm | 1 |

1. Begin by cutting all of the steel as indicated in the cutting list. Label each with the item number on it using a marking pen and set aside. Take note of the mitre cuts for the SHS to ensure that they are cut the correct way.

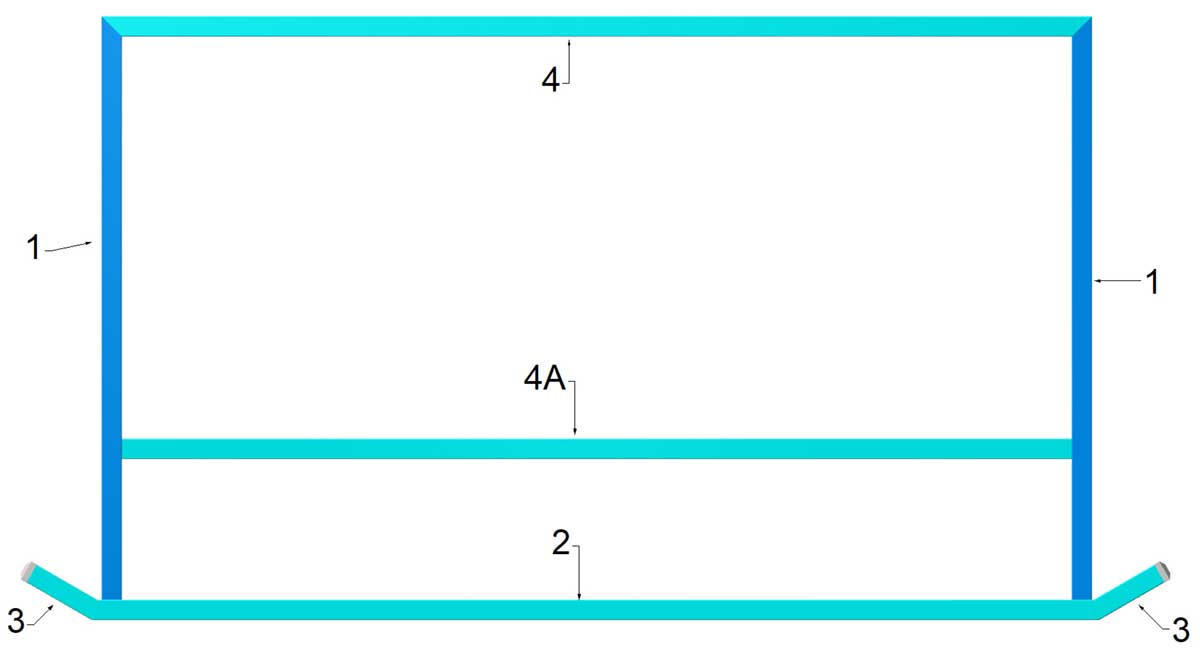

2. Tack weld the front frame as shown in diagram 1. Check that the frame is square and fully weld. Repeat for the rear frame. Refer to diagram 1.

3. Secure the front and rear frame in an upright position and tack weld items 5, 6 and 7 as shown in diagram 2. The lower edge of items 5 should be 400mm up from the ground and item 6 should be installed in the centre of the front and rear frames as shown in diagram 2.

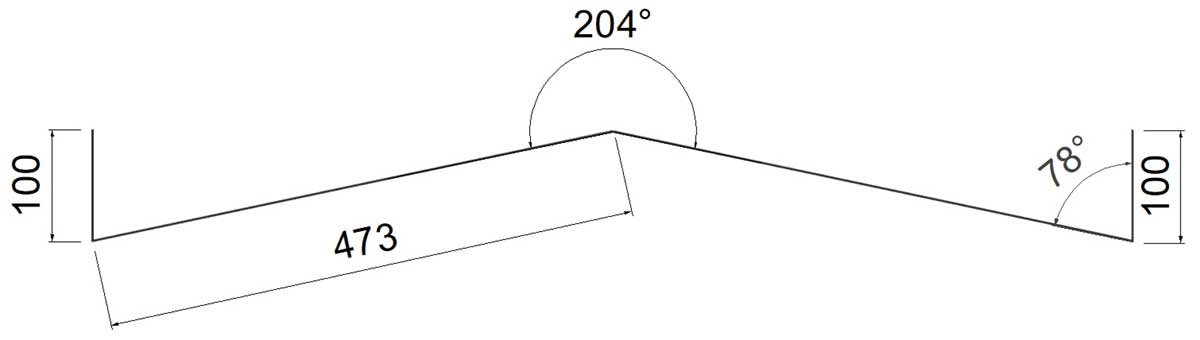

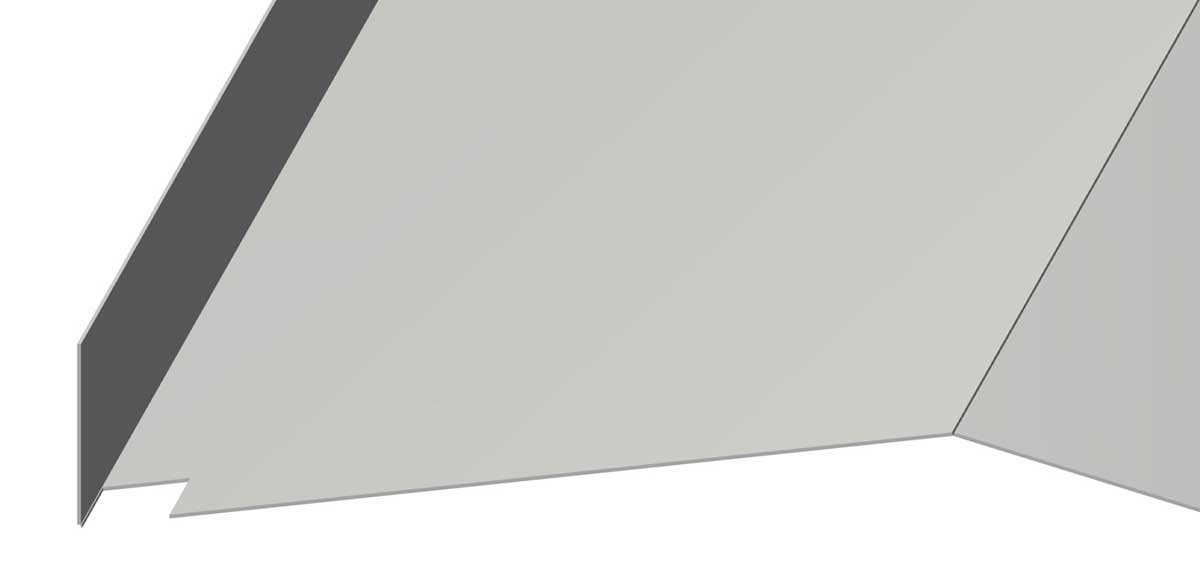

4. Cut and fold sheet for the tray as shown in diagram 3. The length of the sheet is 2440mm. Refer to diagram 3.

5. Cut notches in the corners of the sheet approximately 45mm x 45mm square. These are to fit around items 1. Refer to diagram 4.

6. Install the tray sheet into the frame and secure with self-drilling tek screws through the front and rear of the sheet into items 1. Refer to diagram 5.

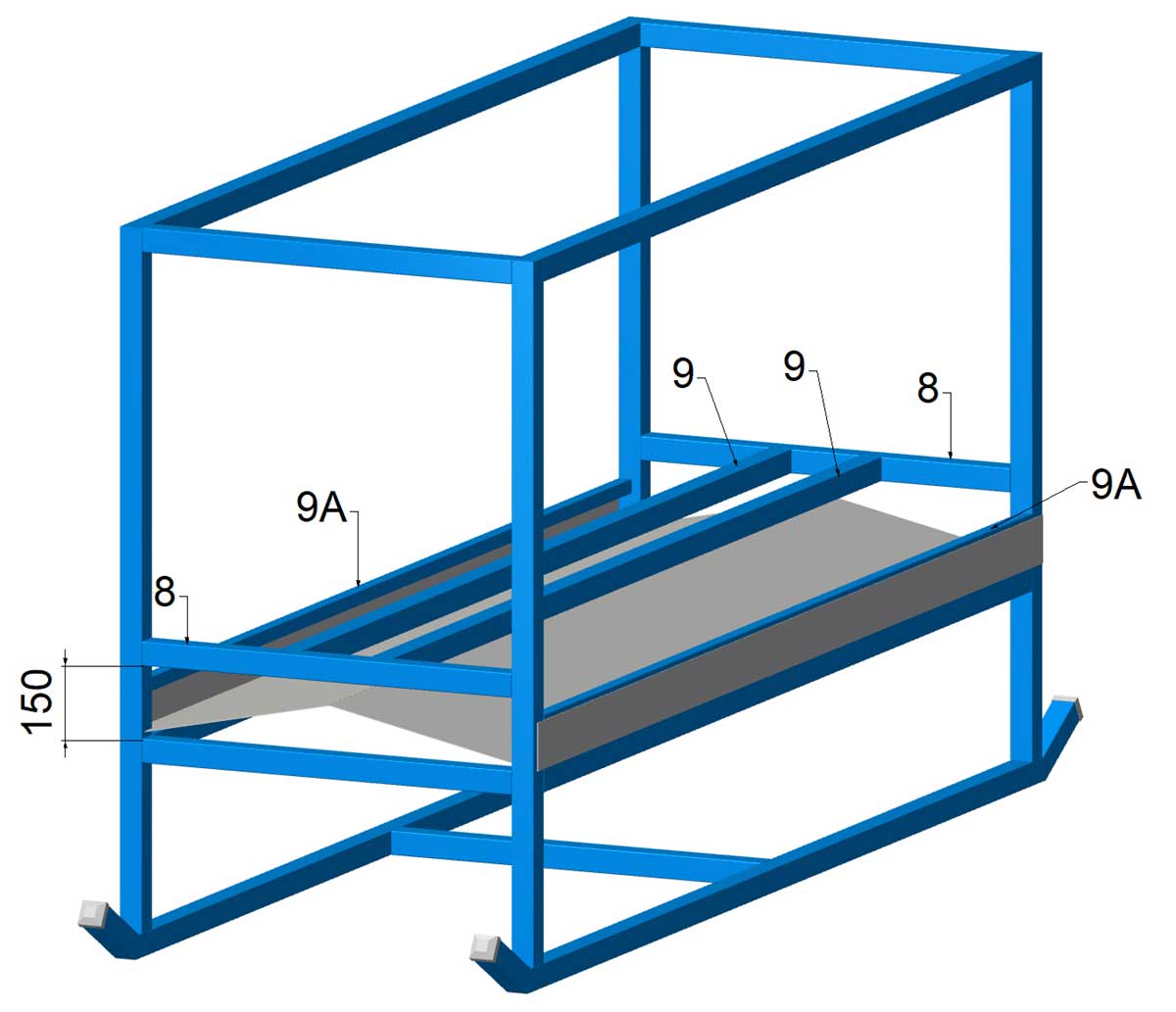

7. Weld items 8 in place.

8. Weld items 9 in position. These should be located in the centre of items 8 and spaced 150mm apart. Weld items 9A in place. Items 9A should be a couple of millimetres above the top edge of the tray sheet. Refer to diagram 5.

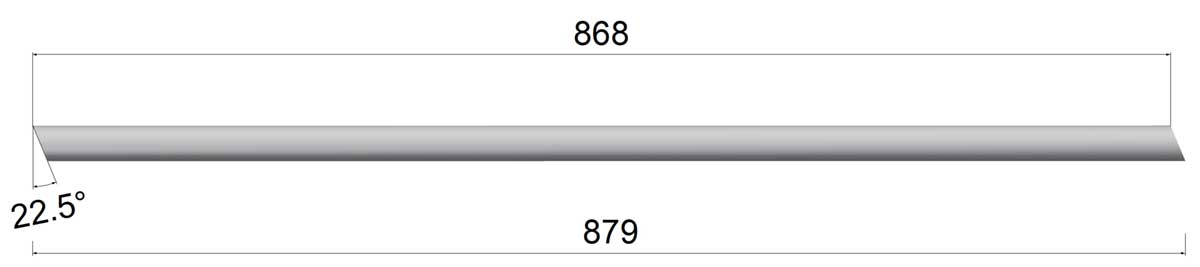

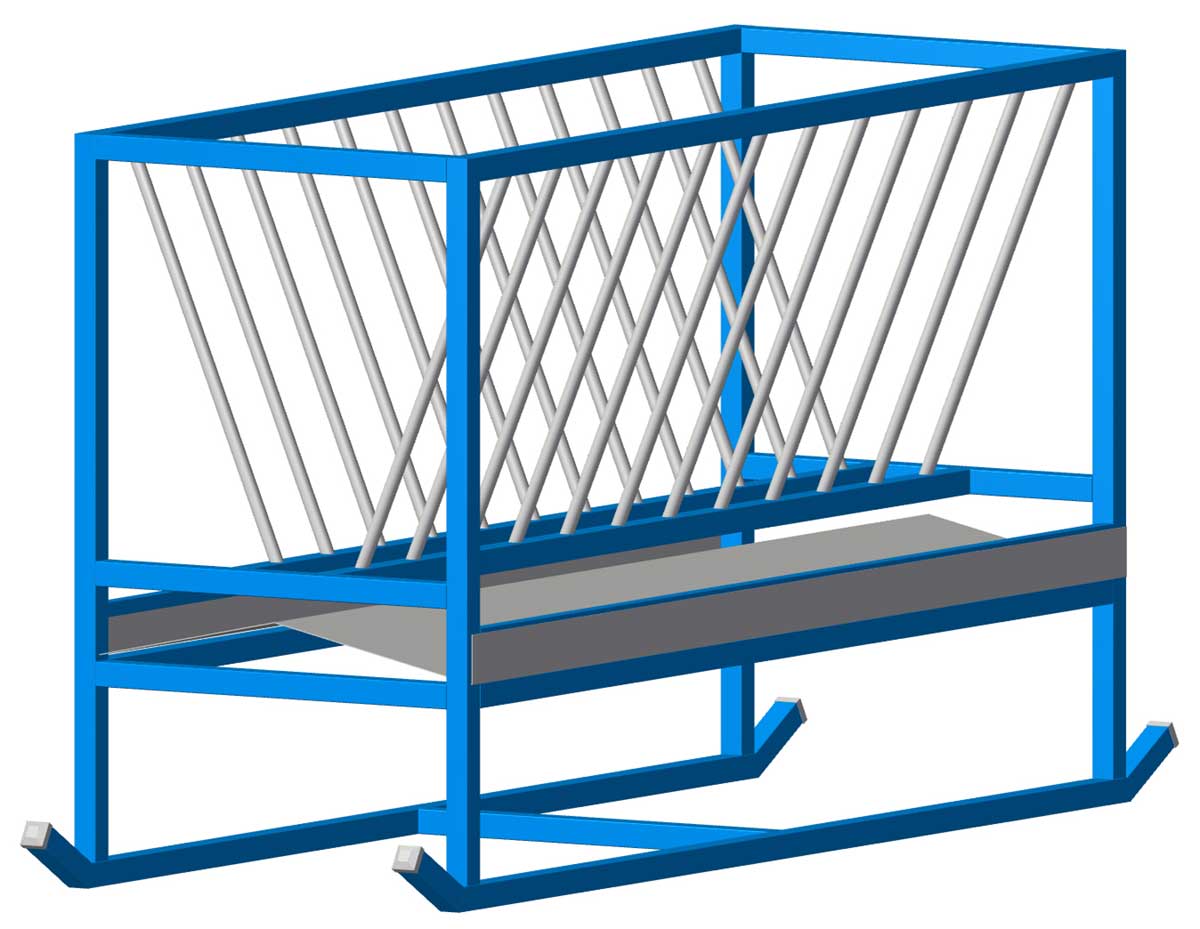

9. Cut one of the pipe bars to size. Note that the overall length of the pipe is 879mm. Refer to diagram 6. Check that it is the correct length and angle by trail fitting it before preceding to cut the balance. Refer to diagram 6.

10. Weld the pipe bars in place as shown in diagram 7. The pipes should be spaced approximately 163mm apart.

11. Cut the end sheets to size. These should be 1080mm x 900mm. Secure these in place using self-drilling tek screws or rivets. Refer to diagram 8.

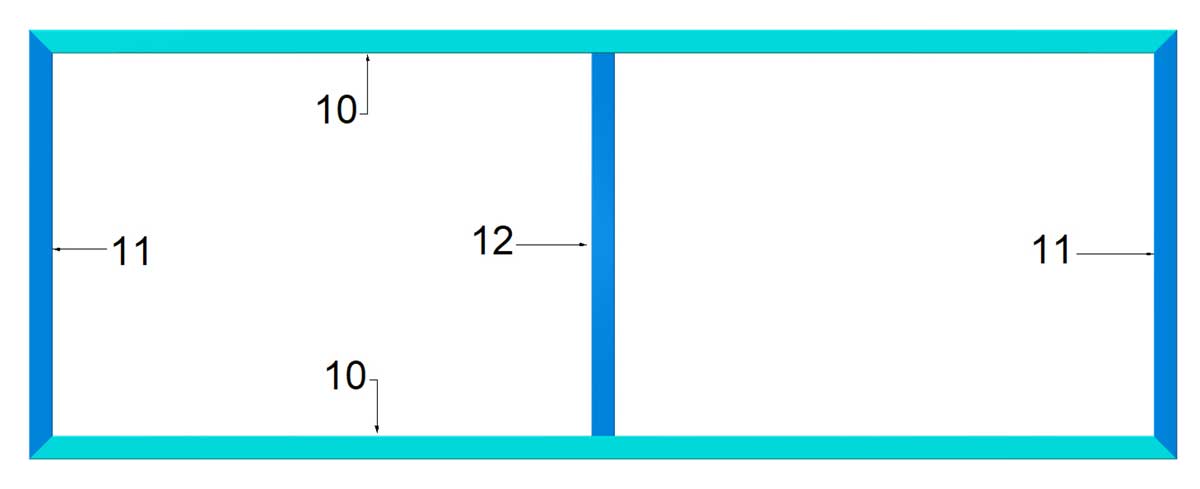

12. Tack weld items 10,11 and 12 together to form the roof frame. Recheck that the frame is square and fully weld as shown in diagram 9.

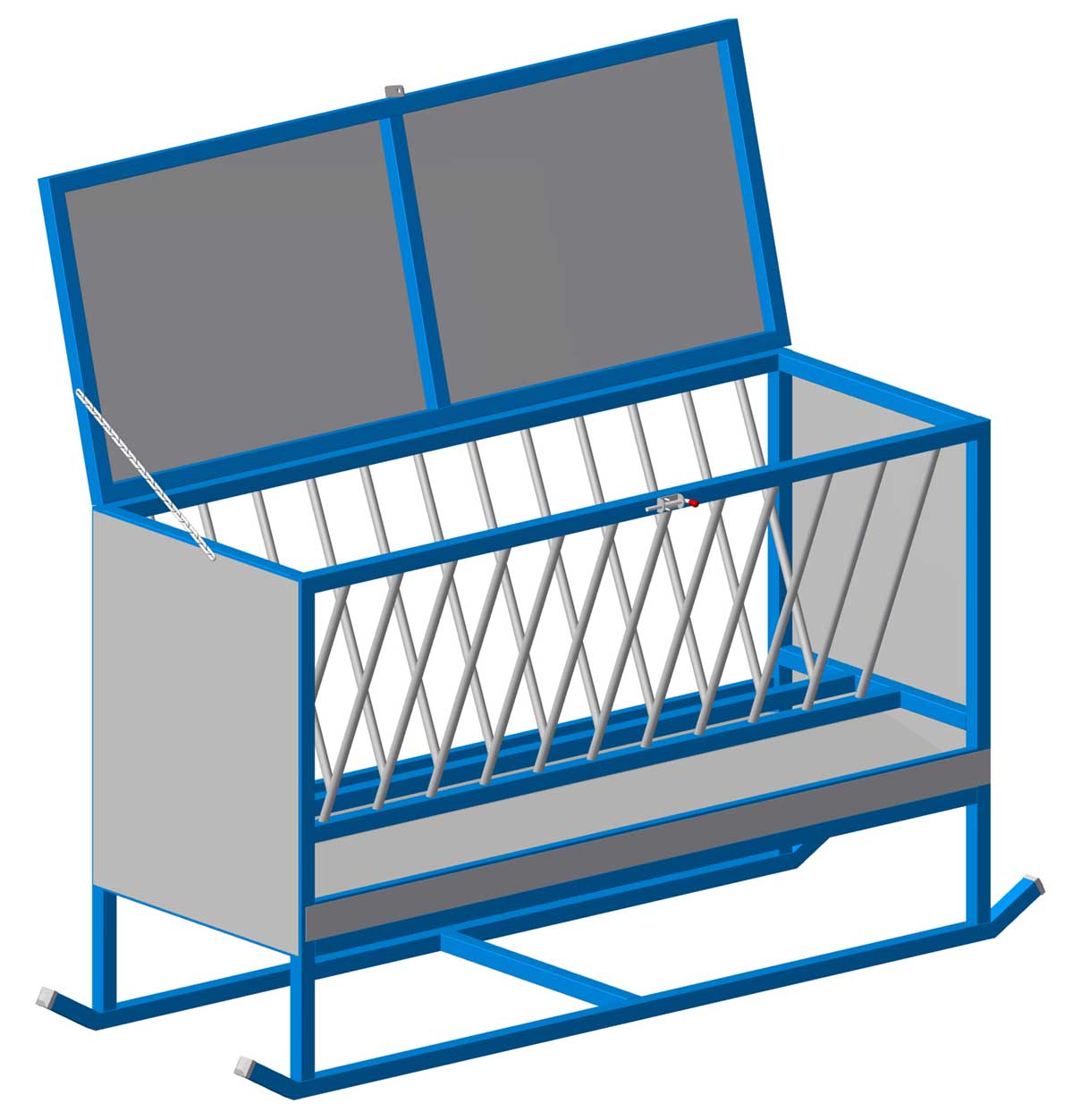

13. Cut the sheet for the roof which should be 2440mm x 900mm. Secure the sheet to the roof frame using pop rivets or self-drilling tek screws.

14. Install the hinges as shown in diagram 10. It is a good idea to make sure that the hinges that you use will not allow the roof to slide sideways and come off the hinge pins. The hinges shown are normally available in a left hand and a right hand version and are ideal for this purpose.

15. Cut a piece of 32x5mm flat bat 80mm long and drill a 14mm hole approximately 20mm up from the bottom for the spring bolt pin.

16. Weld the flat bar and spring bolt in place as shown in diagram 11. The flat bar is welded to the roof frame whilst the spring bolt is welded to the hay rack frame.

17. Cut a piece of galvanised chain approximately 800mm long and weld one end to item 7 of the hay rack frame and the other end to item 11 of the roof frame. This is so that when the roof is open, it will not fall all of the way back.

18. Clean any welds using a grinding disc or flap disc and paint as required.